Manufacturing has reached new heights as companies work to meet not only a surge in demand but an uptick in customization. Customizing products leads to the production of smaller batches, along with constant changes, which just leads to more waste.

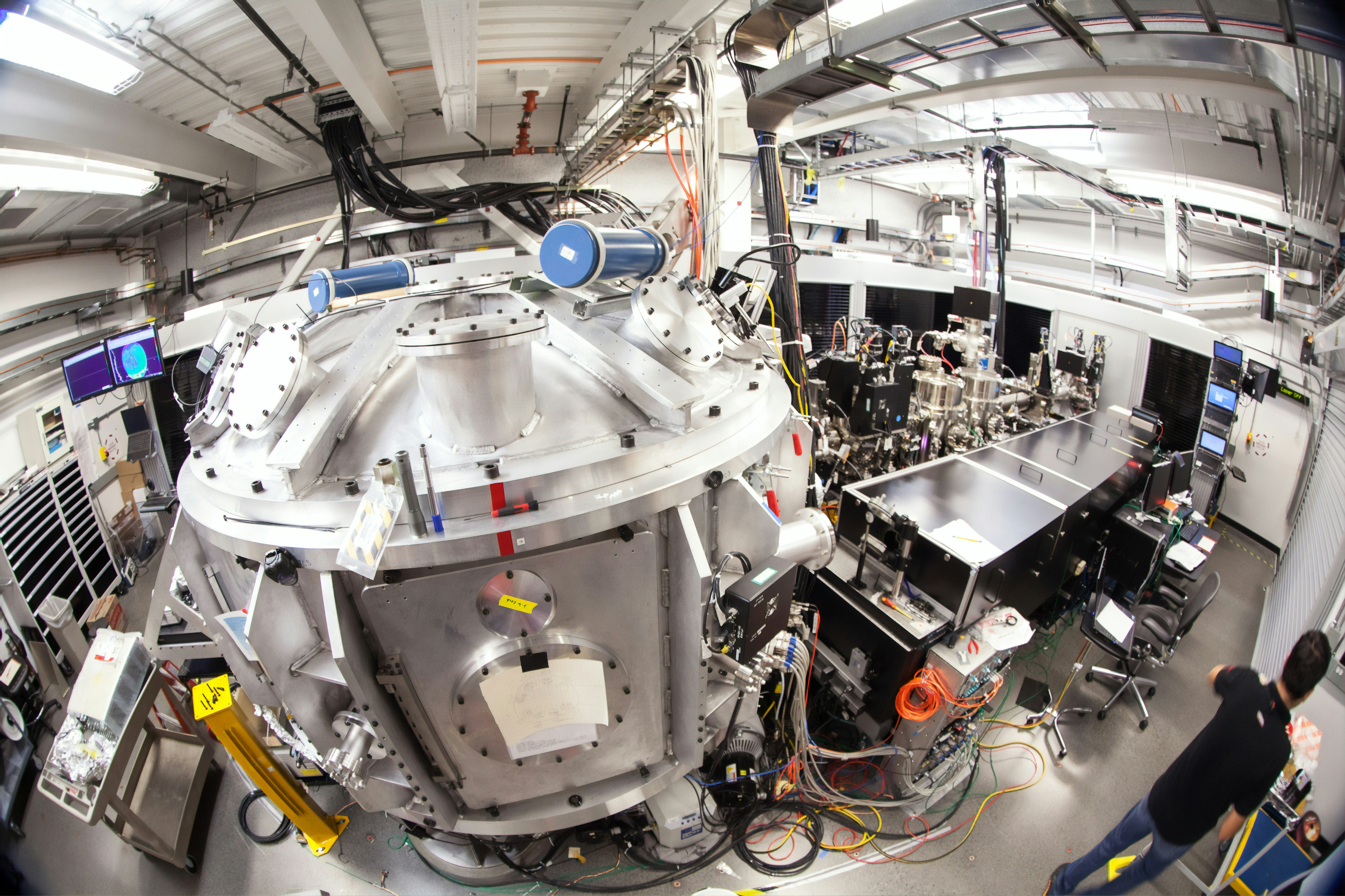

Manufacturers are now left to try and reduce their footprint and cycle times while maximizing just how much they can make off each batch produced for greater optimization. There are new capabilities for processing data that are allowing companies to go from a reactive approach to a proactive management technique, thanks to a collaboration with big data, machine learning, and artificial intelligence.

What is intelligent manufacturing?

Intelligent manufacturing, or smart manufacturing, is the utilization of real-time data analysis, machine learning, and artificial intelligence in the manufacturing process. Intelligent manufacturing allows these companies to maintain a data-driven, full-circle view of their operations—starting from supply chains, through the manufacturing process, and right down to the testing of products and overall customer satisfaction.

By taking this data in real time, companies are able to predict critical events and take the proper action to avoid any issues from arising. A wide range of solutions can be used to better understand equipment, processes, and products, with a more transparent view of the insights that such sensory data can bring to the forefront.

Intelligent manufacturing is also not restricted to just one field within the vast land of manufacturing. It’s a sensible solution to industries ranging from electronics, medical devices, and auto production, to even pharmaceutical and chemical manufacturing as well as consumer packaged goods like a water dispenser.

Benefits of Intelligent Manufacturing

There are many benefits to intelligent manufacturing, but perhaps the greatest of all being the ability to proactively detect an oncoming issue and respond accordingly. This not only improves the quality of your production but your yield and overall equipment effectiveness. Smart manufacturing also opens doors to different business opportunities that manufacturers may not have been aware of, creating new revenue streams and possibilities for new advantages in your respective marketplace.

For example, in sales and marketing, intelligent manufacturing paves the way for understanding and adapting to customer preferences. Analytics and data visualization help supply chains to forecast and better prepare the management of inventory. This has become a process that can change within the blink of an eye, and 5G technology has become a great asset to this development. 5G networks support high connection density and keep real-time data analysis at just that, real time.

Smart manufacturing can be used to enhance products and process quality with intelligent statistical process control. In being able to understand these processes, intelligent manufacturing helps with regulatory compliance in bringing products to a consumer stage. In having a better grasp of these analytics, it gives a greater feeling of ease to regulators that there is an understanding.

Smart Manufacturing Uses

From considerations in chemical development to launching a data analytics company, intelligent manufacturing is becoming more of a popular system to bring companies to the next level of the 21st century, by monitoring the following.

- Product quality

- Machine learning to accurately model and process results

- Equipment maintenance

- Management dashboards for data visualization

- Supply chain analysis for forecasting and inventory management and optimization

- Customer and product analysis and segmentation

- Account management and pricing consideration

- Yield prediction

All of these facets and more tangible areas of smart manufacturing are what organizations are relying on to better grasp just what their customers are thinking of their products and what they want more of going forward. This opens new business opportunities in enhancing consumer experience. With intelligent manufacturing, this can all happen while keeping transparency and adhering to all regulatory standards within a variety of industries.